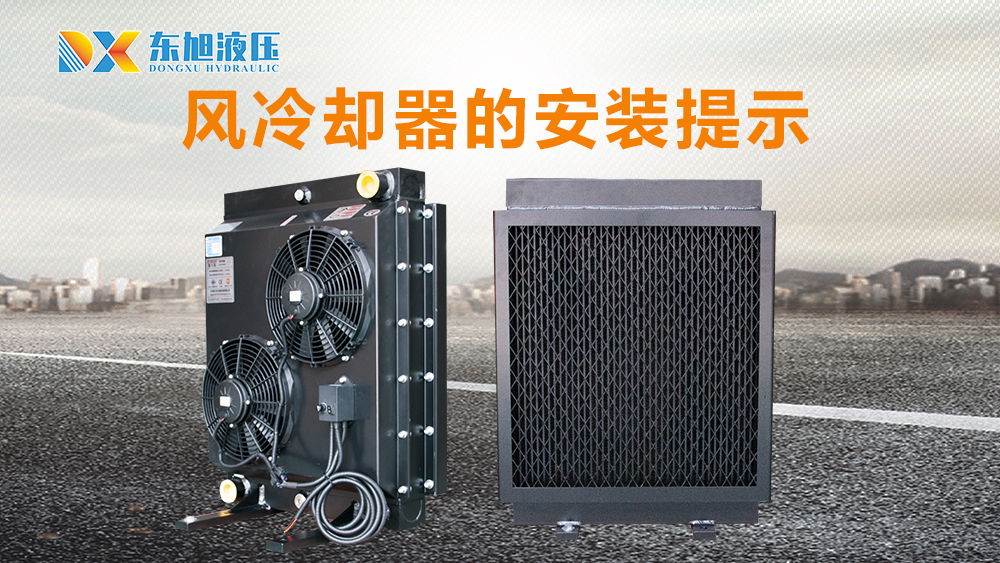

1. The installation position of the cooler should avoid vibration and impact, smooth air inlet and exhaust channels, and firmly installed.

2. The circuit connection must be completed by a professional electrician.

3. The surface of the cooler may have high temperature, must have adequate protection or place it in a place not easily accessible.

4. When connecting the inlet and outlet fittings of the cooler, the outer six (four) corners of the oil port must be fixed with a spanner (see Fig. 4), and then the fittings should be tightened, otherwise it will cause damage and deformation of the cooler and lead to leakage.

5. The cooler's oil port in and out is interchangeable, but there must be necessary measures to ensure that the pressure of the radiator core can not exceed 0.8Mpa.

5-1 When the cooler is used in the dosing pump circuit, a 0.5Mpa bypass check valve must be added to the oil inlet pipe due to the pulse pressure that will be generated when the system is in action.

5-2 cooler bypass valve outlet pipe directly back to the return pipe, the return pipe diameter must be greater than the inlet pipe path area of 1.5 times. (It is recommended that the outlet pipe of the bypass valve return to the oil tank independently or circulate the cooler independently.) Please use high-pressure air to remove dust once a week.