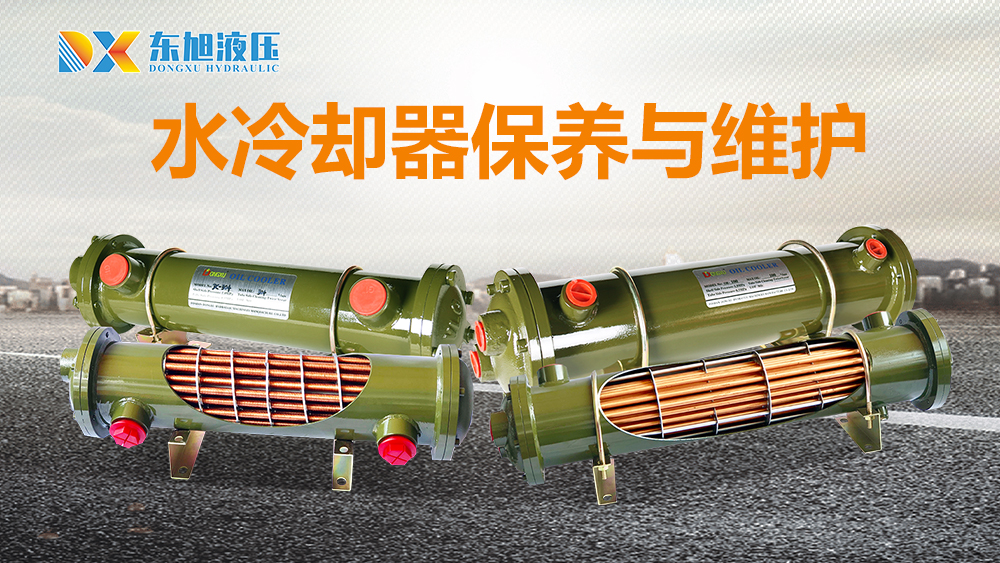

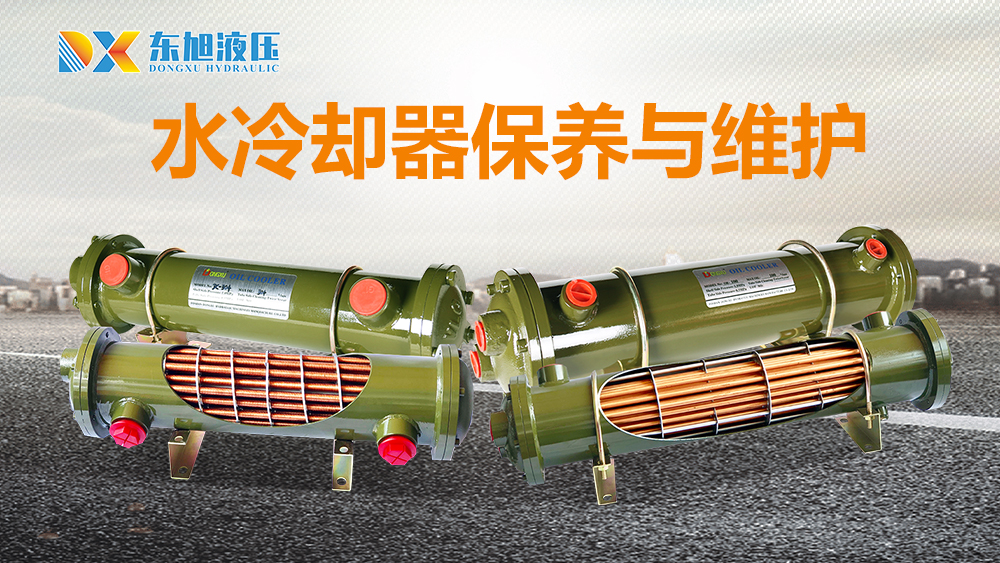

Maintenance of the water cooler

● Water cooler is a device placed in the cooling water circuit to control the temperature of lubricating oil by using the temperature of cooling water.

● Its heat transfer tube adopts purple copper tube rolled out with heat dissipation fins, which can make the two liquid mediums with certain temperature difference achieve heat exchange, so as to achieve the purpose of lowering the oil temperature and ensuring the normal operation of the equipment.

● Cooler long-term work, the cooler tube surface will accumulate scale and increase the thermal resistance and flow resistance, so that the heat transfer performance is gradually reduced, so as not to ensure that the cooler requirements. Obviously, the focus of maintenance should be placed on dirt cleaning, here are several cleaning methods for reference:

Method 1: the use of electric pipe cleaning tools, that is, driven by an electric motor for rotary movement of a flexible shaft, the end of the shaft set of nylon brush or steel wire brush for rotary scrubbing, and through a non-leakage cover to the water injected into the shaft around, in order to scrub out the loose dirt in a timely manner.

Method 2: with a round tube, one end of the welded and tube inner diameter similar to the wire brush while rotating while advancing, dirt can be deposited in the inner lumen of the tube, will not produce dirt thicker and thicker to make advancing more difficult, this method is more often used, but labour-intensive.

Method 3: the use of high-pressure pump (pressure 10 ~ 20Mpa) spray high-pressure water for flushing, the effect is better, mainly used for cleaning between the tube.

Method 4: the use of sponge ball on the heat exchanger tube for automatic cleaning. According to different layers of scale with different hardness of the sponge ball, for special hard scale, can be used with a "band" of emery sponge ball. Its role is to use the softer and elastic sponge ball into the heat exchanger tube, sponge ball compression and tube walls are in contact with the ball and the tube wall to produce relative motion, constantly friction tube wall, will be removed from the deposits.

Method 5: often replace the cooling water, because the water use will produce scale, grease scale, rust scale, which is also a reason for the clogging of the copper pipe. Disassemble the front and back cover, use the air gun to blow every hole in the copper pipe, blow out the dirt, in the front and back cover, 0 ring if there is damage to replace the

水冷却器的维护

●冷却器的故障多半由冷却器管引起的。

●由于腐蚀、汽蚀、磨损而使管壁减薄和穿孔,也由于热胀冷缩,流体运动时产生的振动而造成的连接处及其他性损坏。冷却器管破损后两种介质将互相渗合,应及时进行维修,有以下方法供参考:

方法1:找出破损的冷却器管,用管堵把两端堵死。管堵的锥度为3~5度之间,管堵材料硬度应低于或等于管子硬度,堵死的管子总数不得超过总数的10%。

方法2:取出破损管,更换新管重新胀接。

方法3:管端与管板连接处渗漏,应重新胀接。如果腐蚀严重,应更换管束。

方法4:冬季停用的冷却器应放进腔内介质,以防冻裂冷却器。